Simplifying CTE Complexity: How Districts Deliver CTE Labs Without the Headaches

CTE is one of the clearest ways districts serve students and strengthen their communities, building career pathways that are employer-led, grounded in the local economy, and prepare learners for college and career. But delivering successful CTE labs is uniquely complex.

These spaces require far more than furniture and floor plans: industry-recognized equipment, infrastructure coordination, safety-by-design, credential alignment, instructor readiness, and long-term flexibility as technology evolves.

This article explains why CTE projects often become difficult (especially when decisions are made in silos) and outlines practical strategies districts can use to simplify complexity, reduce risk, and deliver industry-aligned labs that work from day one.

What you’ll get out of this article:

- Why CTE labs are fundamentally different from typical learning spaces (they’re systems, not rooms)

- The hidden risk behind most CTE delays and overruns: fractured ownership and too many disconnected vendors

- A practical approach to simplify complexity through early integration

- Four moves that reduce risk and increase instructional impact:

- start with credentials, not catalogs

- design workflow before equipment layouts

- build safety into the environment

- choose partners who integrate the whole system

- Proof in practice: how Georgetown ISD delivered a multi-pathway, future-ready CTE complex by simplifying complexity through integration

How Districts Deliver Industry-Aligned Labs Without the Headaches

CTE is one of the clearest ways a district serves its community.

When a district builds strong, in-demand career pathways — health science, skilled trades, advanced manufacturing, IT, automotive, construction — it’s doing more than expanding electives. It’s building a future-ready workforce engine that helps local employers find the people and skills they’ll need for the next decade.

That’s why the best CTE programs don’t just create opportunities for students. They create capacity for communities.

They help students graduate with real options (credentials, confidence, and direction). And they help community businesses fill real roles, especially in industries where the talent gap is growing and the stakes are high.

But delivering that kind of program requires more than curriculum. It requires spaces built for real work. And that’s where districts hit the part no one talks about at the ribbon cutting:

CTE labs are complex. Not because leaders lack vision. Because CTE environments are systems, not rooms.

Why CTE Labs Are Different

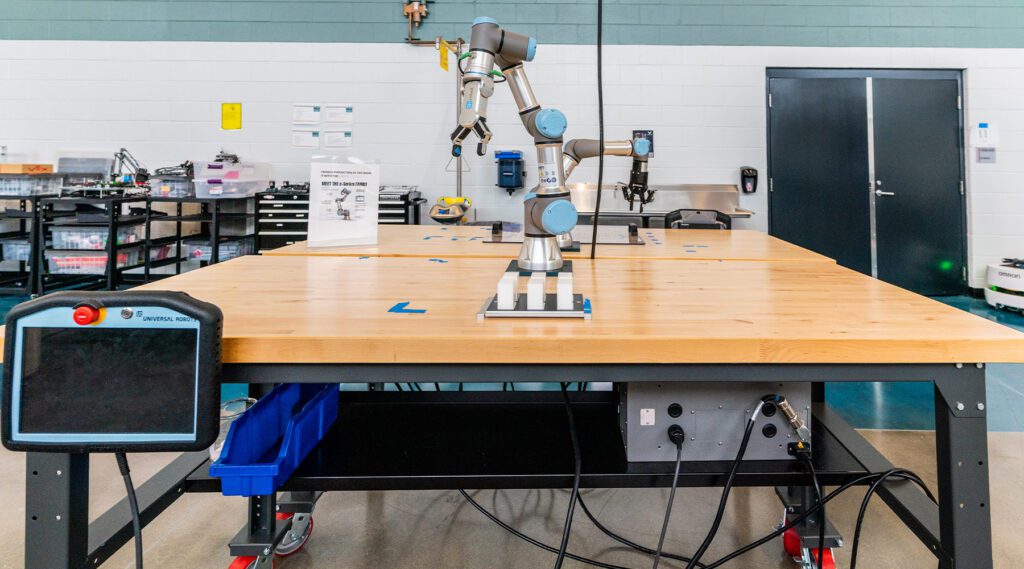

A general classroom is mostly an instruction space. A CTE lab is an instruction space and a production space and a safety-regulated environment, all in the same footprint.

A welding lab isn’t “tables and chairs.” A healthcare simulation lab isn’t a “flex room.” An advanced manufacturing lab isn’t just “cool equipment.”

CTE projects force districts to coordinate requirements that don’t naturally live in one place:

- industry-recognized equipment aligned to current standards

- infrastructure (power, ventilation, dust collection, data, safety systems)

- credential requirements tied to workforce certifications

- instructional workflow (supervision, movement, material flow, assessment)

- furniture + storage ecosystems supporting both theory and hands-on project work

- CTE staff upskilling + adoption support

- safety by design (clear sightlines, protected storage, predictable movement)

And in CTE, one missed detail doesn’t just cause inconvenience. It creates delays, redesign, cost overruns, or worse, safety risk and underuse.

The Hidden Risk: Too Many Cooks in the Kitchen

If you’ve delivered a major learning environment project, you already know the feeling.

One vendor owns furniture. Another owns equipment. Another owns safety. Certification guidance is separate. Teacher training is “later.” Construction timelines shift. Installation becomes its own beast.

Nobody is doing bad work. But nobody owns the full system. That’s the real risk: fractured ownership.

And when the project gets fractured, the problems are predictable:

- equipment doesn’t match infrastructure

- safety visibility gets compromised

- install sequencing becomes chaotic

- credential requirements force late changes

- teachers feel overwhelmed at launch

- budgets drift and expectations collapse

CTE lab overruns rarely happen because districts are careless. They happen because complex systems break when decisions are made in silos.

The Better Model: Treat CTE Like an Ecosystem

The districts that deliver high-performing CTE labs do something different: They integrate the work from day one.

Instead of starting with product lists, they start with outcomes and design backward, treating equipment, infrastructure, certifications, safety, training, furniture, and storage as a connected ecosystem.

It starts with better questions:

- What careers are we preparing students for?

- Which certifications will prove they’re job-ready?

- What does our regional workforce actually need?

- How will teaching run hour by hour in this space?

- What safety routines must the environment support?

- How do we preserve flexibility as equipment and technology evolve?

When those answers are clear, the complexity doesn’t disappear, but the decisions stop fighting each other.

Four Practical Moves That Simplify CTE

Districts don’t need a perfect process. But they do need a disciplined one. These four moves consistently reduce risk and raise outcomes.

1. Start With Credentials, Not Catalogs

Certifications shape equipment, layout, infrastructure, and safety requirements. If credentials are an afterthought, redesign is almost guaranteed.

Good planning keeps certification alignment early, so it doesn’t become late-stage pain.

2. Design Instructional Workflow Before Finalizing Equipment

Many labs get designed for machines. But labs succeed when they’re designed for teaching.

Instruction requires supervision, sightlines, movement, staging, storage, and routines that work in real conditions, not perfect renderings.

3. Build Safety Into the Space Itself

CTE safety isn’t only PPE and compliance signage. It’s visibility, zone design, and protected storage. It’s predictable movement and teacher proximity.

And it includes psychological safety too: students need a space where they can learn, ask questions, and take supervised risks without embarrassment.

Safety isn’t a checklist. It’s a design outcome.

4. Choose Partners Who Can Integrate the Whole System

This is the biggest simplifier of all. CTE projects require coordination across equipment, infrastructure, certification demands, furniture/storage, install sequencing, and training support.

The more quarterbacking the district must do, the more the project feels like a three-ring circus. The right partner reduces handoffs and gives the district one connected plan.

Proof in Practice: Georgetown ISD’s Future-Ready CTE Complex

Georgetown ISD set out to build a centralized CTE facility preparing students for multiple high-demand pathways including health science, advanced manufacturing, automotive, aviation, culinary arts, and skilled trades.

The vision was big. The complexity was bigger:

- 241,000 sq. ft.

- 1,000+ students per day

- multiple pathways with unique equipment and safety needs

- certification alignment across programs

- teacher adoption critical from day one

- a shared facility that had to flex across student populations and changing program demands

The district didn’t just need equipment or furniture. They needed integration.

“We wanted to find a partner that could quarterback what needed to be done because we didn’t have the bandwidth to do it.”

Robert Thomas, GISD Innovation Facilitator

The result was a future-ready CTE complex with:

- industry-aligned labs built for real workflows

- safer environments designed for supervision and movement

- flexible layouts that can evolve as technology changes

- instructors equipped to teach confidently from day one

Georgetown didn’t just build labs. They built a scalable workforce development model for the community.

The Payoff: CTE Labs That Work From Day One

When complexity is simplified through integration, districts gain:

- fewer surprises and smoother timelines

- stronger alignment between instruction, space, and equipment

- safer environments for students and staff

- higher instructor confidence and adoption

- labs that truly support credentials and workforce readiness

- flexibility as programs and technology evolve

CTE labs aren’t just rooms. They’re launchpads. Simplifying what’s behind them makes it far more likely districts deliver what the community is counting on: students prepared for real opportunity beyond graduation.

Meteor education

Ready for a new approach to CTE?

See how districts are delivering industry-aligned labs that support credentials, safety, and instruction, without adding complexity or risk.